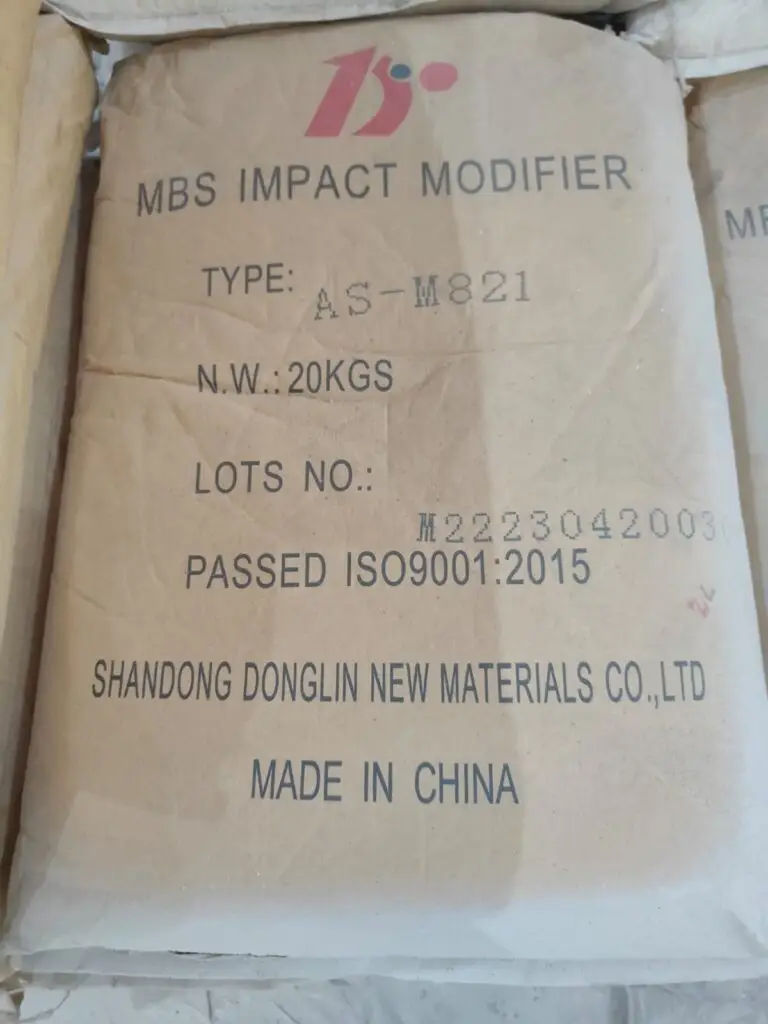

Methyl Methacrylate Butadiene Styrene

Methyl Methacrylate Butadiene Styrene (MBS) impact modifier resins for rigid and semi-rigid PVC applications and engineering thermoplastics. The Kane Ace™ B range is optimized with tailor-made grades for the specific needs of a variety of applications. They add excellent impact efficiency to the end product in opaque to crystal-clear applications and are suitable for use in food and pharmaceutical packaging. Typical MBS impact modifier applications are sheets, food-packaging film, bottles, pharmaceutical blister packs, pipes, fittings…The MBS core-shell structure consists of a butadiene-based rubber core, which acts to absorb or dissipate impact energy, and a methyl methacrylate styrene graft polymer covering the core. This graft layer improves the adhesion between the polymer matrix and the impact modifier.